Technology

Process

We are specialized in casting production using the following technologies: Sand casting (sand-clay mixtures);

Resin sand casting (cold hardening mixtures);Investment casting.

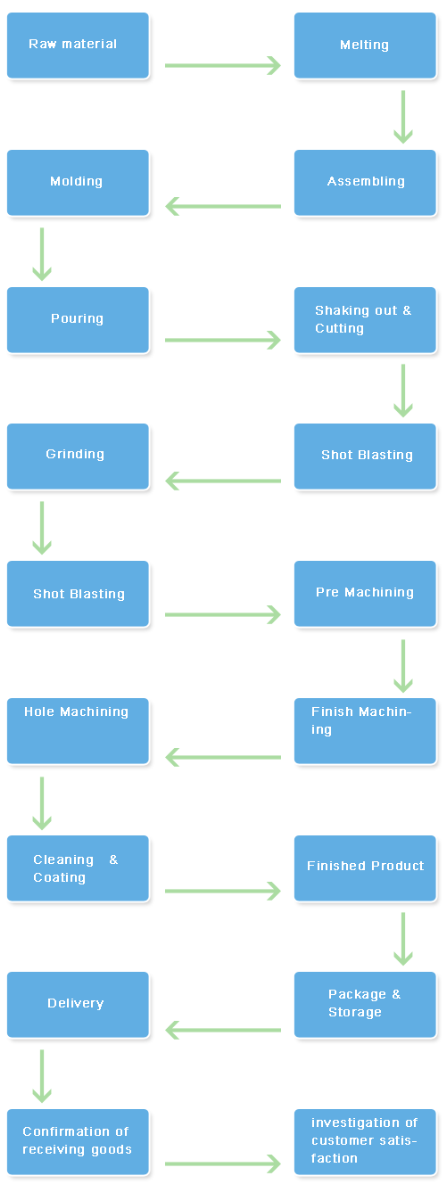

Process Flow

Casting workshops

- total area: 33000m2

- production capacity: 160 000t/year

- melting furnaces:

Electric medium frequency furnaces:(max. charge – 3t) – 8pcs, (max. charge – 1t) – 4pcs.

Electric arc furnaces: (5t) – 1 pcs, (10t) – 1 pcs.

Refining furnace: 15t – 1 pcs.

Automatic molding lines: 6

- heat treatment furnaces: 4 pcs.

- time for making: pattern equipment – at least 10 days, casting - at least 6 days

- our own testing laboratory

- we can provide the following reports:

o Ultrasonic defects detection

o X-ray defects detection

o Magnetoscopy

o Mechanical properties tests

o Chemical composition

- we do rough and finish machining (see Machining potential)

The alloys we use:

Iron:

• Gray iron

• Ductile iron

• High-temperature iron

• Bearing cast iron

Steel:

o Carbon steel

o low-alloy steel

o alloy steel

o stainless steel

o wear-resisting steel

o heat-resistant steel

Machining potential:

Turning machining

vertical turning and boring

Milling, face-milling

horizontal boring-and-turning

deep boring

Face-planing

vertical planing

gear machining*

conical-shaped teeth straight and spiral

Cylindrical tooth straight, angular and herringbone

barrel tooth

Worm thooth

Grinding*

а) cylindrical grinding

b) internal grinding

c)surface grinding

d) centerless grinding